Home » Keywords: » inspection equipment

Items Tagged with 'inspection equipment'

ARTICLES

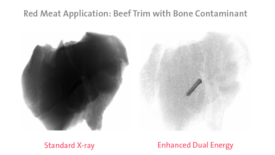

Inspection and detection equipment reach new levels of flexibility for peak food safety

X-ray, metal detection, checkweighing and vision systems help processors ensure food safety

January 22, 2019

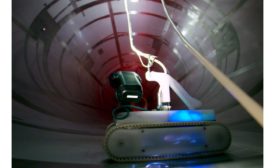

Inspection equipment evolves with automated operations

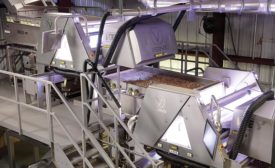

Packaging design impacts inspection equipment

July 14, 2017

Never miss the latest news and trends driving the food safety industry

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing