Preventive maintenance is one of the six basic prerequisite programs, the others being product identification, traceability and recalls, Sanitation Standard Operating Procedures (SSOPs), Good Manufacturing Practices, and education and training. Over 20 years ago, these programs were actually included as Critical Control Points (CCPs) in many companies’ Hazard Analysis and Critical Control Points (HACCP) plans. These requirements had an effect on food safety. When the United States finalized the Seafood HACCP regulation in 1995,[1] what were once CCPs became prerequisite programs that could be used to address potential safety issues, very much like the sanitation preventive controls or allergen preventive controls that have evolved from the enactment of the Food Safety Modernization Act (FSMA) and the regulations developed to ensure its enforcement. In fact, the following statement from the preamble of the Seafood HACCP regulation summarizes how this evolved:

Sanitation, especially those issues related to cleaning and sanitizing, and routine maintenance aimed at assuring safe operation of equipment should now be included in the prerequisite program and not be considered to be CCPs.

How preventive maintenance is defined and managed differs between operations. Some focus simply on equipment, whereas other companies may incorporate elements from the calibration program. But however it is managed, it is an essential prerequisite program for food safety. Failure to properly manage and maintain the program can potentially create situations that cause biological, chemical, and physical hazards. The Clostridium botulinum type E outbreak of 1982 was directly attributed to improper maintenance of can reformers used in the Alaskan salmon canneries. Prior to 1983, cans were shipped to the canneries as flattened blanks. These blanks were loaded into a magazine. The can reformers were designed to remove the blanks using “picker fingers” and move them to a unit that formed the blank into a can body. A seamer then put the end on the can. Improper loading and adjustment of the unit resulted in small tears on the bodies of some cans, which allowed the botulinum spores to gain access to the cans. Pflug[2] indicates that the 2007 Castleberry’s botulism outbreak was caused in part by poor systems maintenance.

Improper maintenance of cutters or choppers has resulted in metal contamination of foods that caused injuries and resulted in recalls. The use of metal detectors, magnets, and X-ray machines has helped reduce these incidents. But X-ray machines and metal detectors will not remove all metals, only those of a certain size. Operators must understand that if a product becomes contaminated with metal, even if that metal is so small your detectors do not find it, it is still adulterated and subject to a recall.

Preventive maintenance benefits processors in more ways than just food safety. It can enhance quality, protect equipment, and improve operating efficiencies. In fact, a well-managed maintenance program can save companies a great deal of money in different areas. It can also reduce aggravation. Consider this: Why do most people do some maintenance on their cars just before they go on vacation? Because you don’t want to break down in the middle of summer with kids in the car. The goal is to have a relaxing vacation, not be stuck in Podunk, USA.

Developing a Preventive Maintenance Program

A processor’s preventive maintenance should include the elements in Table 1. The first step, however, is for the processor to establish the scope of the program and how it will be set up. Who will develop the program and be responsible for managing it? The plant engineers? A maintenance group? Will production play a role? Will calibration activities be incorporated into the program? Will the program be a paper program or a maintenance management software program? And what will be the goal or objective of the program? An effective objective could be articulated as seen below, for example:

A processor’s preventive maintenance should include the elements in Table 1. The first step, however, is for the processor to establish the scope of the program and how it will be set up. Who will develop the program and be responsible for managing it? The plant engineers? A maintenance group? Will production play a role? Will calibration activities be incorporated into the program? Will the program be a paper program or a maintenance management software program? And what will be the goal or objective of the program? An effective objective could be articulated as seen below, for example:

Objective: To develop, document, implement, and maintain a preventive maintenance program that ensures safe and sanitary operation of all equipment essential for maintaining quality and safety of products. This program may also be used to monitor operational efficiencies and to evaluate machine performance that may be used for future equipment purchases.

Based on the scope of the program, a master list of all equipment that requires maintenance must be assembled. Depending upon the size of the facility and the scope, this could be a very large list. With a large operation, the list might be broken down by line or area of the plant. There really is no right or wrong way to do this. At a minimum, the master list should include the following:

• Equipment name

• Location

• Serial number

• Description

• Maintenance schedule

• Responsibility

• Procedures

The master list of equipment sets the stage for determining whether the company moves toward incorporating predictive maintenance into the overall maintenance program. So, what is predictive maintenance?

Predictive maintenance is designed to help determine the condition of in-service equipment to predict when maintenance should be performed. This approach promises cost savings over routine or time-based preventive maintenance, because tasks are performed only when warranted.

With preventive maintenance, the operator adheres to a rigid schedule; with predictive maintenance, work is done whenever needed. Predictive maintenance is based on the condition of the equipment, not the expected life span. With preventive maintenance, the processor may do scheduled maintenance, but the reality of the situation might be that the equipment did not need to be maintained. Not every piece of equipment is amenable to a predictive maintenance program. To incorporate something into a predictive maintenance program, the company needs measureable performance parameters and linkage to a maintenance management program.

What do we mean by “measurable performance parameters”? These are nondestructive tools that allow real-time monitoring of how the equipment is performing. Among these tools are infrared, acoustic, corona detection, vibration analysis, sound level measurements, and oil analysis. Infrared analysis is somewhat self-explanatory. The warmer something is, the greater the infrared signature. This particular technology is considered by many to be the most effective of all the monitoring tools. It can be employed with high- and low-speed equipment.

By contrast, there is vibrational monitoring, which is the most expensive of the monitoring techniques and hard to set up. As the technology has evolved, users now can monitor equipment along three axes. This technology may be sophisticated, but it cannot be utilized to its fullest without well-trained operators who understand the technology and how it can be applied.

As noted, these very sophisticated technologies are meant to monitor equipment as it is being utilized. The instruments must be linked to a maintenance management software program so that the data can be analyzed and the people managing the system know when it is time to do the necessary maintenance.

Obviously, setting up a predictive maintenance program is expensive. The necessary monitoring devices must be installed and configured, baselines for each piece of equipment established, and the company must purchase and set up a maintenance management program and link it to the monitoring devices.

Once these systems are set up, processors have the opportunity to experiment. As an example, a processor might want to evaluate whether a high-performance lubricant might enhance operational efficiencies. Monitoring infrared signatures, acoustic signatures, or vibration could very well tell the processor that they need to apply the lubricant only once every 2 weeks instead of every 3 days. The lubricant might be more expensive, but performance is improved and maintenance costs are decreased.

A Real-Life Example

One example of where predictive maintenance can benefit companies is for monitoring chain wear. There are many tools that can show whether a chain is stretched and should be replaced; they give the stretch in percentage, and you can track the process over time, start making predictions, and test alternative maintenance regimes. Hence, it fits well in a predictive maintenance approach. By trying to find identical chain applications, for instance, identical machines running the same shifts in parallel, we can set up controlled tests to find the optimal maintenance regime. This is an area where a lot of savings can be realized; it is not uncommon to extend chain and sprocket life by a factor of three or four. This setup allows customers to test a variety of things, different brands and types of chains, lubrication technologies, viscosities of the oils within a technology, frequency of application, cleaning methods and frequency, etc.

Most companies determine these things based on visual appearance and noise. Visual appearance can disclose things about corrosion on the outside but is a poor indicator of the internal state of the pins and bushings where the mechanical action takes place. Noise is often a sign that maintenance is overdue. Noise means there is metal-to-metal contact, which leads to excessive wear.

Chains can be a large cost component for a maintenance operation. Chains with a replacement cost of over $60,000 are not uncommon, excluding the cost of downtime, which can be a multiple of that.

Preventive Maintenance Program Components

Maintenance schedules: Maintenance schedules must be established for each piece of equipment. In many cases, a single piece of equipment might have several schedules. This might include daily lubrication, weekly adjustment of something, and a systems tear-down every 6 months. These schedules should be based on risk to the business or the products, which means that the food safety team should be involved in the process. And the team should include someone from maintenance. As noted, if a piece of equipment is included in a predictive maintenance program, there will be no set schedule.

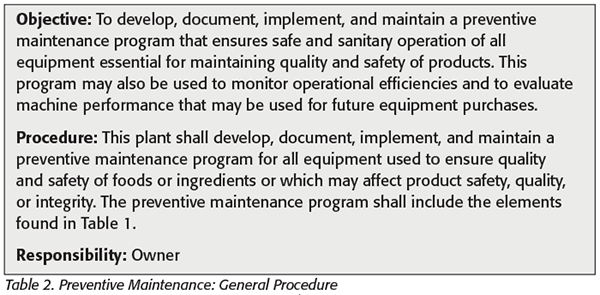

Documented procedures: Each and every maintenance activity should be fully documented utilizing a standard format. Most food processors have adopted one of the Global Food Safety Initiative audit schemes, so creating procedures utilizing a standard format is a normal part of doing business. A standard format for a generic preventive maintenance program may be seen in Table 2. Additional fields or sections could be added for activities such as records or record keeping, corrective actions, or verification activities. When developing preventive maintenance procedures, the company should draw on the manuals provided by the equipment manufacturers, the risk assessments they have conducted, and their own experiences. In most cases, equipment manuals are far too detailed and bulky for everyday use, so procedures need to be streamlined.

Documented procedures: Each and every maintenance activity should be fully documented utilizing a standard format. Most food processors have adopted one of the Global Food Safety Initiative audit schemes, so creating procedures utilizing a standard format is a normal part of doing business. A standard format for a generic preventive maintenance program may be seen in Table 2. Additional fields or sections could be added for activities such as records or record keeping, corrective actions, or verification activities. When developing preventive maintenance procedures, the company should draw on the manuals provided by the equipment manufacturers, the risk assessments they have conducted, and their own experiences. In most cases, equipment manuals are far too detailed and bulky for everyday use, so procedures need to be streamlined.

It is also imperative to properly document and keep records of emergency repairs. Too many companies neglect this task. When asked about emergency repairs, they do not have those records but can tell you that there was “downtime” from their downtime logs.

Record keeping: Records are an essential element for any program. There is no legal requirement for how records are maintained. Processors can maintain hard-copy records or utilize an electronic system. As noted, the electronic system is a must for any company wishing to adopt predictive maintenance. Records are essential for ensuring that equipment is properly maintained. Integral parts of any record-keeping program are management review of records and verification that the work is being done and done properly. If one reads through Pflug’s paper cited earlier,2 the Castleberry group failed to properly maintain and calibrate certain devices essential for ensuring proper operation of the retorts. Proper review of these records may have minimized potential damage from the incident.

Many companies utilize one of the many electronic maintenance management systems. These programs may be developed in-house using programs such as Excel or Access, or processors can choose a commercially available product, of which there are many options. Features that an operator might look for in an electronic system include:

• Maintenance scheduling

• Flags when items are due

• Flags for past-due items

• Cost integration (maintenance hours, capital costs, parts, downtime, etc.)

• Procedures for doing work

• Automatic entry by workers

• Ability to verify that work has been done

• Print capability (summaries, schedules, equipment registers)

• Ability to “talk” to other systems

• Compatibility with predictive maintenance technology

The biggest problem with such systems is setup. It takes a great deal of time and effort to enter all the necessary information into the system. In fact, from what I have seen in the industry, most processors who are utilizing an electronic maintenance management system are not using it to its full capability. They are simply not using one or more features that the program offers. Perhaps the best use of a system I have ever seen was a processor that incorporated their maintenance management into SAP. The program manager could capture all hours involved with maintenance and emergency repairs, plus the cost of spare parts and downtime for each unit operation in every line in the plant. He could demonstrate how much it cost to operate each unit operation and/or piece of equipment in a line, and therefore, the cost to operate each line. This allowed the company to determine which pieces of equipment were operating efficiently and which were not. They used these data year after year to further improve efficiencies.

Tool reconciliation: Tool reconciliation should be part of every company’s preventive maintenance program. What goes into the plant must be accounted for. The best analogy is a surgical nurse. He or she counts all the materials that a doctor may use prior to the start of a surgery: sponges, scalpels, retractors, etc. When the surgery is done, all must be accounted for. One of the best means for ensuring that tools are properly accounted for is the use of tool or shadow boxes for different pieces of equipment. These boxes will be set up with all the tools necessary for routine maintenance, and each tool will have a place. The boxes will be properly secured and accessible only to designated persons. When a project is completed, the tools are returned to the box and the box locked. Since everything has a place, it is very easy to confirm that everything is where it should be. Another good means for ensuring tools are properly reconciled is to ask the maintenance crew to supply their own tools. People tend to watch out for their own. Of course, if this is the route a company chooses, it needs to provide its crew with a yearly tool allowance.

Lubrication: Lubrication is a hot button during third-party audits. The lubrication procedures should not only describe how and when to lubricate but should also specify the type of lubricant and how much is used. Ideally, the lubrication records should capture all this information. The lubrication program should also include procedures describing how food- and nonfood-grade lubricants are identified and stored to ensure that the proper material is used. Food- and nonfood-grade lubricants should be stored in separate areas. Processors are now color-coding lubricants and/or the grease guns used to apply them. Since this is an extremely important issue, suppliers of lubricants have stepped forward to help ensure better control of lubricants. The vendors are now color-coding lubricants and grease guns used for application. In addition, many processors are making a conscious effort to eliminate nonfood-grade lubricants from their operations. This is not always possible, however. Manufacturers of lubricants are also aware of this issue and are working hard to develop food-grade products that will stand up to high-stress operations.

Handovers: One important element of every maintenance program is the handover program. When a maintenance task is completed, it is up to the quality group to ensure that not only was the work done and done properly but also that the equipment has been cleaned and sanitized prior to the handover. The company must develop forms to ensure that the repairs have been done. These forms must include a space for quality review and sign off.

Training and Education

Each and every person involved in the preventive maintenance program, especially anyone working with equipment used for predictive maintenance, must be properly trained on all procedures and that training must be documented. These training sessions must be based on documented procedures that were addressed above. Training should include how to do the work, how to keep records, and even how records should be reviewed. Record review is even more important under FSMA, which mandates that records be reviewed on a regular schedule by a qualified individual or under the supervision of such a person.

Summary

Preventive maintenance is one of the basic prerequisite programs for HACCP. A well-organized, -managed, and -maintained program can minimize the potential for biological, physical, and chemical hazards or adulterants, ensuring the safety and wholesomeness of the food. New technologies enable processors to expand their preventive maintenance program to include predictive maintenance. With this program, operators can continuously monitor equipment during operations and do maintenance based on performance parameters instead of a time schedule. This technology requires the installation of an electronic maintenance management system. The program must be fully documented, which includes required record-keeping protocols, and all staff involved in the program need to be trained. Think develop, document, implement, and maintain, and then verify that it is working as designed.

Richard F. Stier is a consulting food scientist.

References

1. U.S. Food & Drug Administration. 1995. “Procedures for the Safe and Sanitary Processing and Importing of Fish and Fishery Products,” Code of Federal Regulations, Title 21 Parts 123 & 1240, December 18.

2. Pflug, I. 2010. “Science, Practice and Human Errors in Controlling Clostridium botulinum in Heat-Preserved Foods in Hermetic Containers.” J Food Prot 73:5, 993–1002.

Incorporating Predictive Maintenance into Your Preventive Maintenance Program